Project Overview

This project involved the rerouting and reconstruction of the main sewage line for Cadbury Plc, Agidingbi, Ikeja, Lagos. The initiative was undertaken to improve waste management efficiency, strengthen the plant’s infrastructure compliance with environmental regulations, and ensure sustainable operations for one of Nigeria’s leading food and beverage manufacturers.

Client: Cadbury Plc

Location: Agidingbi, Ikeja, Lagos

Category: Commercial

Vendor: K-Lincon Construction Company

Service: Sewage Line Rerouting & Waste Management Upgrade

The original sewage system had become inefficient due to structural wear, outdated design, and increased operational demand from the facility. Our team was contracted to deliver a modernized, durable, and environmentally safe sewage line that would handle high-capacity waste flow without leakage, contamination, or disruption to factory operations.

Scope of Work

The project covered the following major phases:

• Excavation & Site Preparation

• Deployment of heavy-duty excavators and construction equipment.

• Careful trenching and clearance in compliance with safety regulations.

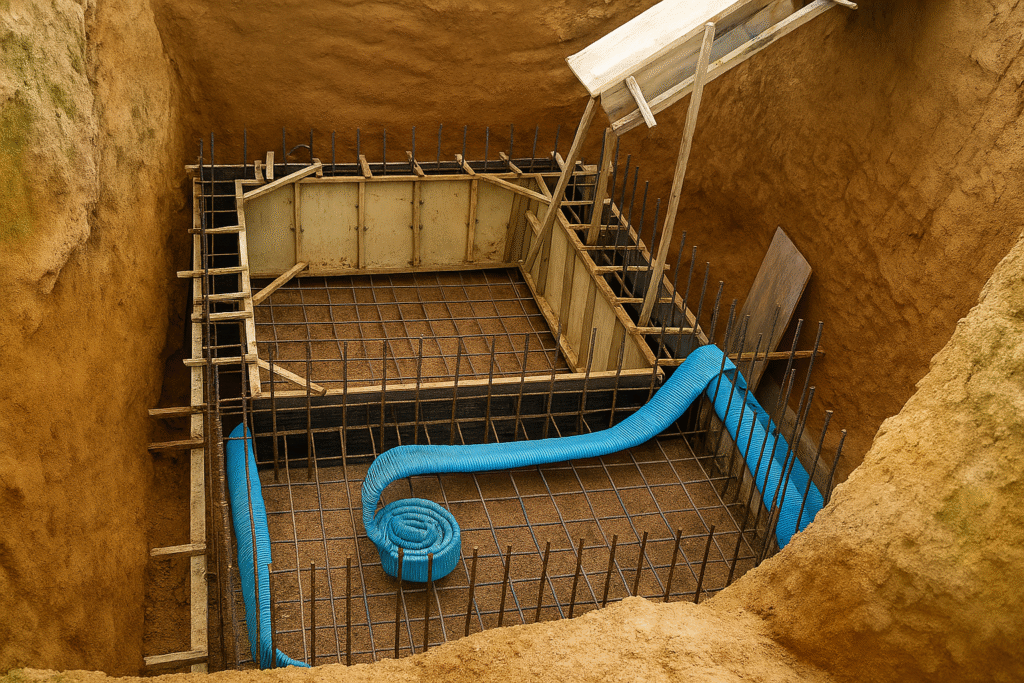

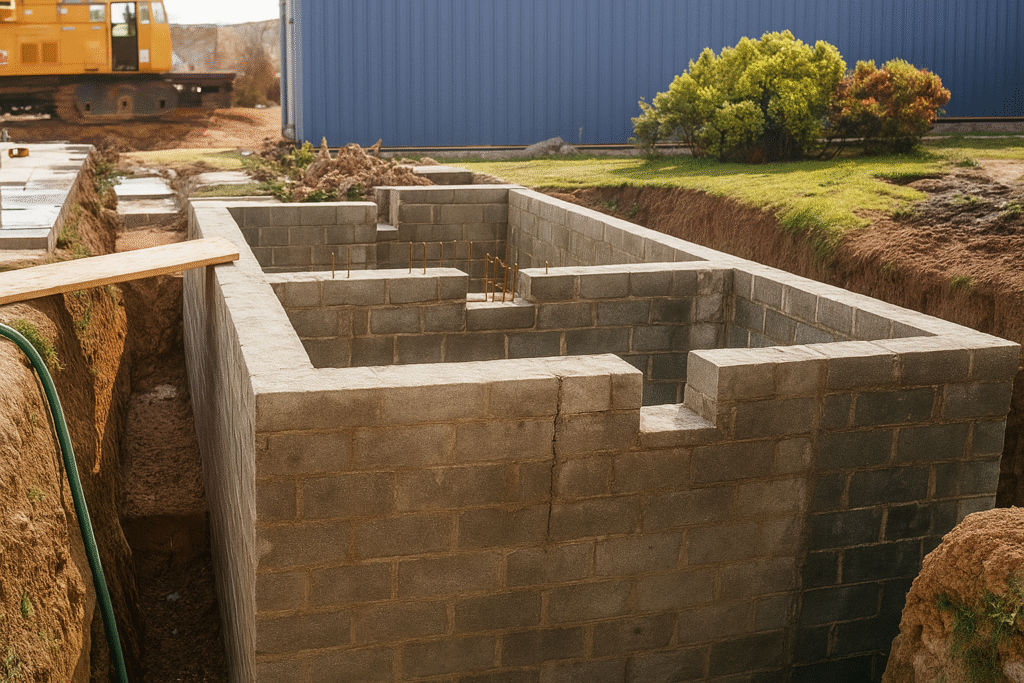

• Structural Reinforcement

• Laying of reinforced concrete and steel frameworks to create durable chambers.

• Use of high-quality rebar and waterproofing techniques to prevent structural failure.

• Sewage Line Installation

• Rerouting of existing pipelines with upgraded PVC and concrete piping systems.

• Integration of access points and inspection chambers for easy maintenance.

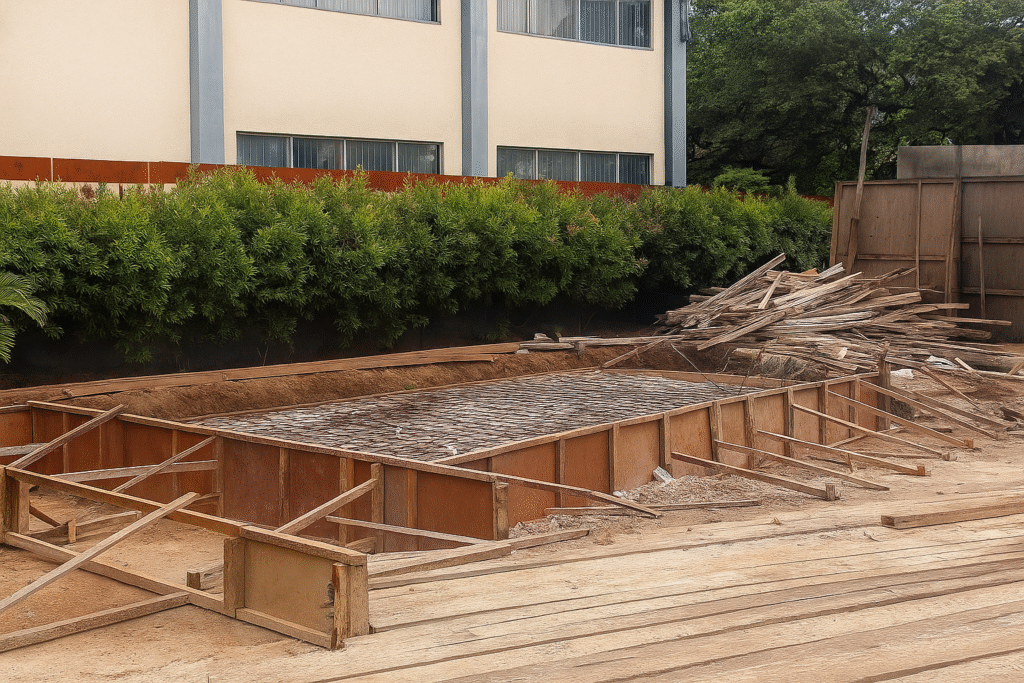

• Concrete Works & Casting

• Precision pouring of reinforced concrete to ensure durability.

• Casting of manholes and chamber covers with high-grade concrete for long-term use.

• Finishing & Compliance Testing

• Soil backfilling and surface reinstatement to restore the factory environment.

• Final inspection and testing to confirm flow efficiency, safety, and compliance with environmental standards.

Challenges & Solutions

Challenge: Maintaining operational continuity at Cadbury Plc during construction.

Solution: Work was executed in phases with minimal disruption, ensuring factory processes remained active.

Challenge: Ensuring long-term durability in a high-usage industrial environment.

Solution: We applied extra reinforcement, anti-corrosion coatings, and optimized pipe gradients to enhance flow and reduce blockages.

Project Outcome

• A newly rerouted sewage system capable of handling high-capacity waste disposal efficiently.

• Improved waste management infrastructure for Cadbury Plc, ensuring compliance with Lagos State Environmental Protection Agency (LASEPA) regulations.

• Enhanced safety, durability, and sustainability, minimizing risks of leakage, contamination, or downtime.

Impact

This project plays a critical role in supporting Cadbury Plc’s commitment to sustainability and environmental compliance. By upgrading their sewage system, the company has secured a future-proof waste management solution that aligns with both industrial best practices and government regulations.Our work ensures that Cadbury Plc can continue to operate efficiently, protect the environment, and maintain its position as a trusted household name in Nigeria and beyond.

100+

Completed Projects

20+

Years Of Excellence

100%

Clients Satisfaction